2021 just opened the spring of the boss read to do detector, completely unfamiliar field ah, is no way to start, no contact at all before, no way to get on the ah, so a variety of online to find information, but also scattered, but also from the Internet to buy the product back to disassemble and analyze, but also half-knowledge, so according to their own access to information combined with the purchase of the product to do the analysis, the analysis through their own principle, but also do 4 sets of schematics, but do not know whether the program is feasible, and can not just pick a program to do, so I put 4 sets of programs are done simulation, light simulation analysis of 4 sets of down to basically spent a month's time, the results of the 4 sets of all failures, but also a head of confusion, of course, is not for nothing, and from this also learned a lot of knowledge;

Cases are project to take over, the leadership are arranged to open the mold, my side of the program are not done, said there is no pressure that is a lie, the walk or to walk, so again, the spirit, continue to design new programs, according to the previous ate the “loss” (in fact, not a loss of ha, is the accumulation of experience ....). First to give themselves a point of praise), and then re-integrated a set of programs, programs in all aspects of consideration are taken into account, they also feel that this time should be able to become (this feeling is often very accurate .....) A little metaphysical ha...) In the cautious, I did a lot of simulation calculations, from all aspects of the accuracy of the measurement data, but also on the program around the optimization of the simulation, the program feasibility of basically no problem, the heart is kind of a sigh of relief, there is finally a doorway;

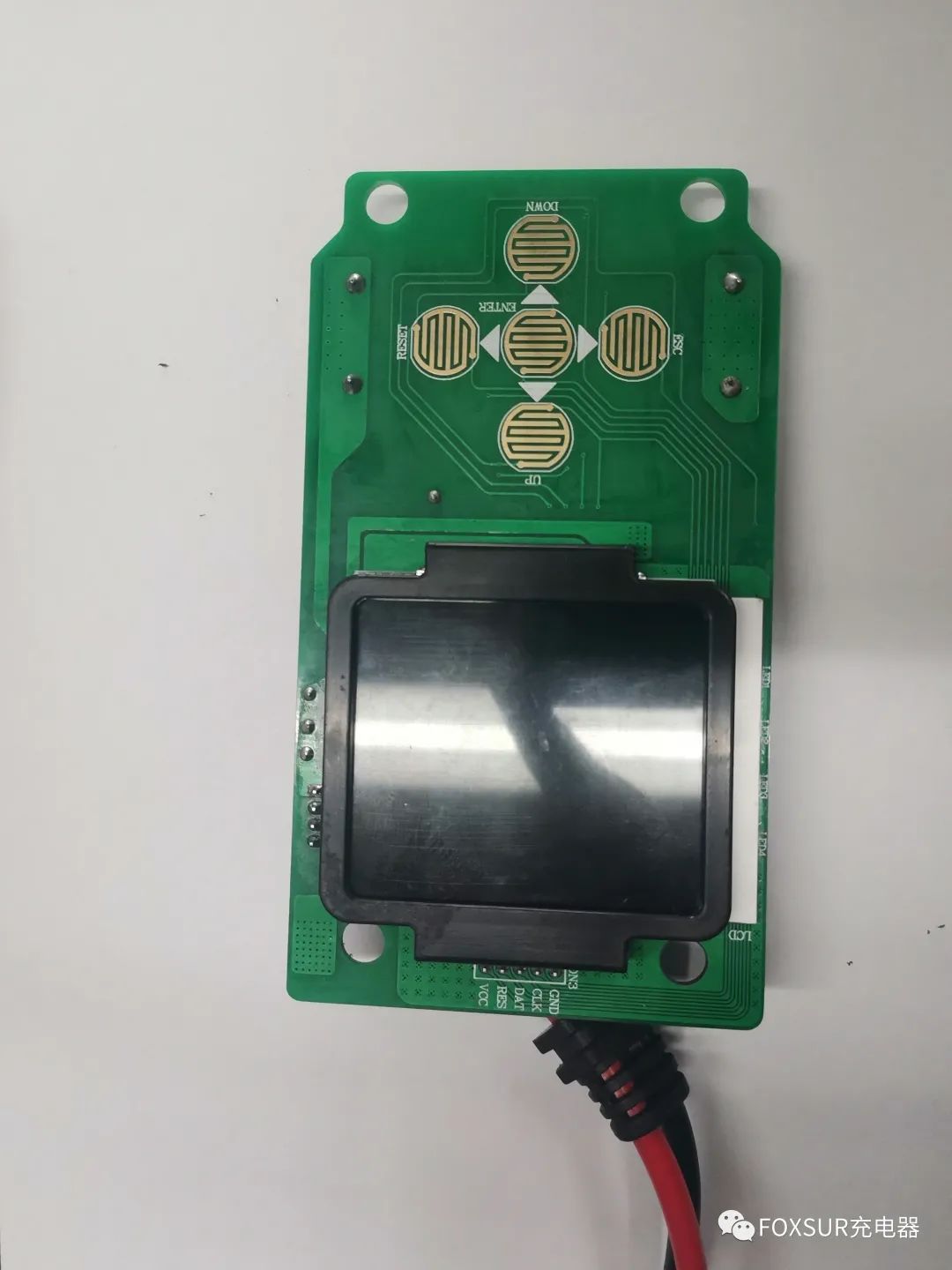

(1) principle is considered to be done below is also the most difficult program implementation, do not know how the program is implemented, so the first DIY version (debugging version), mainly to verify whether the product measurement data is accurate, the PCB board is out of the very fast, 3 days to get sent out for sampling, but the program this piece is a difficult point, how to collect data, data collection, data collection how to deal with the light program writing on the Spent more than half a month, plus board debugging 1 month, finally the measurement data detected, the project can be considered to continue; DIY pictures are as follows:

DIY test version

(2) DIY After the first taste of sweetness, finally began the machine development, machine development is far more difficult than DIY, the product's appearance, functionality, user-friendly design, and so on spend a long time; after a long debugging cycle (about a month's time) the second product is basically out (the basic prototype), the overall test results are considered to be basically through, not satisfied with is the display panel is not designed to be reasonable, looking at the awkward, the measurement data is not stable, there are deviations, but also to continue to optimize

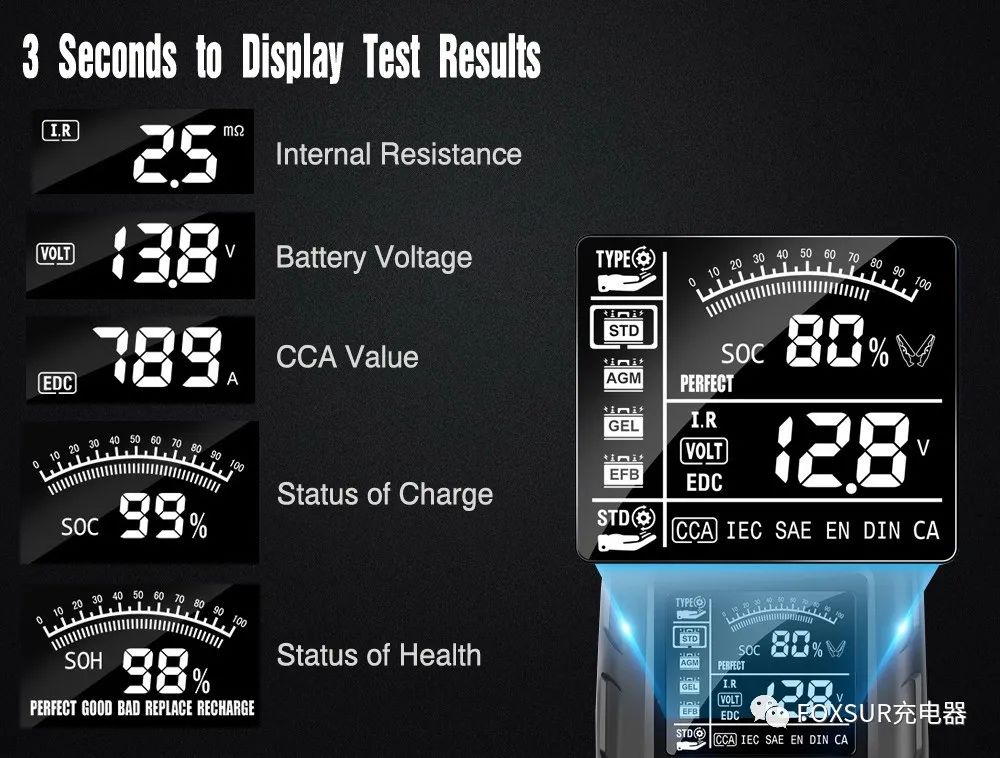

(3) the third version of the second version of the problem of processing, such as measurement data is not stable, for the program and the operation of the discharge circuit adjustment, now basically solved the problem, for the measurement of data to join the software's auto-calibration, the basic stability of the data and its accuracy is quite good, the important thing is that compared with the hundreds of dollars on the market detector I have the data with their basic consistency, which proves that my program is the right idea, secretly happy. The idea of the program is correct, secretly happy. For the LCD display panel is also a lot of thought, mold cost 2 sets, and finally designed a set of more satisfactory interface, without further ado, the third version is as follows:

(4) version 4 is actually the third version of the basis of some circuit optimization and product manufacturing process optimization, to facilitate the production of products, such as assembly interference with the shell, as well as the production of the product, to do some hardware adjustments, while the feeling that the physical buttons are too earth, no sense of texture, so we add conductive rubber buttons, for the conductive rubber buttons, the characteristics of the PCB board copper foil all immersed in gold processing, this cost is high. This cost is high again. Haha. No way to spend or to spend ah.... Compared with the products on the market, the accuracy of the data I basically the same with them, but the cost-effectiveness of this product absolutely crushed 。。。。

(5) By this point the product is basically sort of done and dusted. This is the longest development this year. Of course, the technical content is also the highest, experienced the failure of the anguish, the helplessness of the closed ideas, there is always a defiant “pride”, and finally tasted the joy of success 。。。。 Here to give myself a point of praise.... Good luck with the product ~~~~~~